Key Features

- Low pressure, high-density plasma, good uniformity

- ISM (Inductively Super Magnetron) Plasma Source *ULVAC Patent

- Good repeatability and stability - STAR Electrode * ULVAC Patent

- Superior Process Flexibility - Chamber capable of running both F and Cl processes

- Precise and stable Endpoint Detection - Optical Emission EPD (option), Laser Interference EPD (option)

- Precise wafer temperature control - ESC with backside Helium cooling or Mechanical Chuck

- Easy maintenance - Simple maintenance mechanism

Films

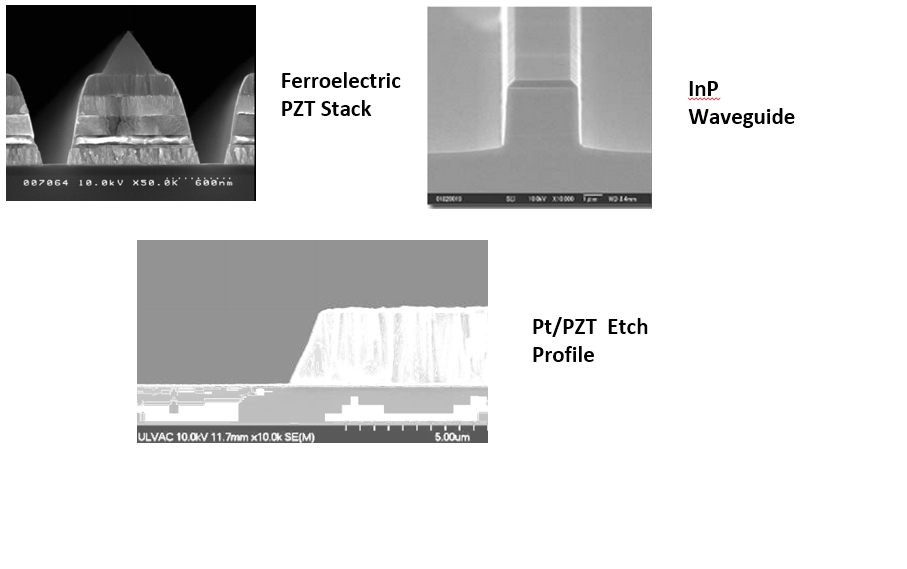

- III-V materials: Selective etching - GaAs, AlGaAs, InGaAs, InGaP, InP

- Insulating Layers: High speed or damage-free etching - SiO2, SiN, Low-K materials, GaAs VIA, InP VIA, SiC VIA

- Organics: Polyimide, BCB

- Metals and Ceramics: W, WSi, TiW, Mo, PZT, STO, BST, SBT, Ir, IrO2, Au, Pt, Ti, TiN, Ta Optical Devices (Laser Diodes, LED, etc..)

- Non-selective etching - GaAs, AlGaAs, AlGaInP, InAlAs, InP, GaN, AlGaN, InGaN, AlN

- ITO, Sapphire Other Devices (MEMS, Stamper for DVD, etc…)

- Si, SiC, Glass, Quartz, Sapphire, C, Diamond-like Carbon, Al, Cr, Mo

Need more information?

At ULVAC, we understand that finding the right product is crucial for optimizing your processes, whether you're scaling up production or maintaining precision in your systems. With our wide range of cutting-edge vacuum technologies and in-depth expertise, we will guide you through selecting the ideal solution tailored to your unique requirements.

Contact ULVAC System Sales & Support For inquiries outside North and South America, please contact ULVAC CorporateSEM Images

.jpg)