This ULVAC system features a tunable neutral network source for uniform etching, low electron temperatures for enhanced profile control, and improved surface flatness. The system offers flexible process chemistry and accurate temperature control with an electrostatic chuck and helium back-side cooling.

Key Features

- Low process pressure, high density plasma, low electron temperature are perfect for quartz glass, Pyrex, LN, LT etc.

- High Density Plasma for increased etch rates

- Flexible process chemistry

- Compact system for etching high-quality glass features

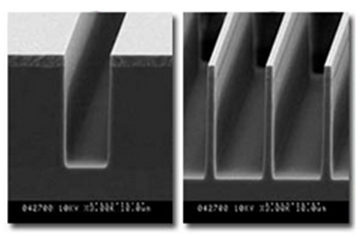

- Good profile control and surface roughness

- Good performance of deep SiO2 etching with PR

- High etching rate of Quartz > 1μm/min, Pyrex > 0.8 μm/min

- Excellent uniformity control

- Cassette chamber is selectable as an option

Applications

- Microfluidics

- Optical MEMS

- Lenses

Need more information?

At ULVAC, we understand that finding the right product is crucial for optimizing your processes, whether you're scaling up production or maintaining precision in your systems. With our wide range of cutting-edge vacuum technologies and in-depth expertise, we will guide you through selecting the ideal solution tailored to your unique requirements.

Contact ULVAC System Sales & Support For inquiries outside North and South America, please contact ULVAC CorporateSEM Image

.jpg)